Product List

- Continuous Carbonization Fur…

- Airflow Carbonization Furnac…

- Dry Distillation Carbonizati…

- Charcoal Powder Mixer

- Charcoal Rods Machine

- Charcoal Tablets Machine

- Charcoal Ball Machine

- Stamping Rods Machine

- BBQ Charcoal Machine

- Charcoal Crusher

- Rotary Tablet Press Machine

- Rotary Shisha Charcoal Machi…

- Wood Powder Machine

- Wood Pallets Mill

- Biomass Pellet Machine

- Charcoal Molding Machine

- Biomass Fuel Machine

- Charcoal Crushing Machine

- Belt Conveyor

- Charcoal Forming Process

Servers

Welcome to HONGRUN Machinery

Continuous Carbonization Furnace

Continuous carbonization furnace makes charcoal from wood, sawdust, bamboo, coconut shell, rice husk, stalk, agro wastes and many other biomass materials. How to Make Charcoal from Biomass Materials? Learn More

The charcoal can be turned to charcoal briquettes with different shapes by charcoal briquette machines.

Charcoal Rod Machine

Charcoal Ball Machine

Charcoal Tablets Machine

Continuous carbonization furnace can be used for recycling electronic waste& scrap metals, such as aluminum capacitor recycling, circuit board recycling, waste wire recycling, and scrap metal paint removing.

Charcoal Ball Machine

Charcoal Tablets Machine

Continuous carbonization furnace can be used for recycling electronic waste& scrap metals, such as aluminum capacitor recycling, circuit board recycling, waste wire recycling, and scrap metal paint removing.

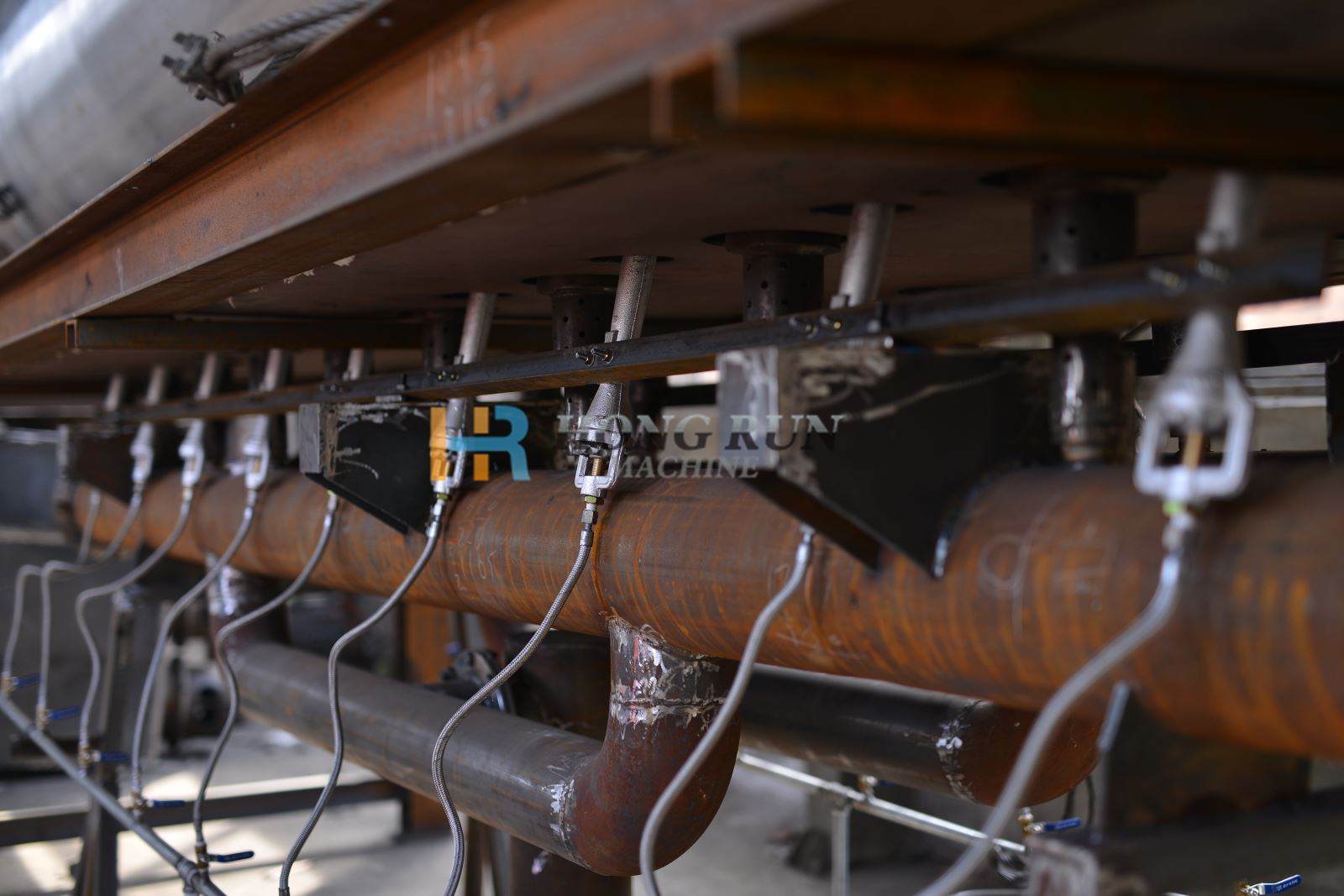

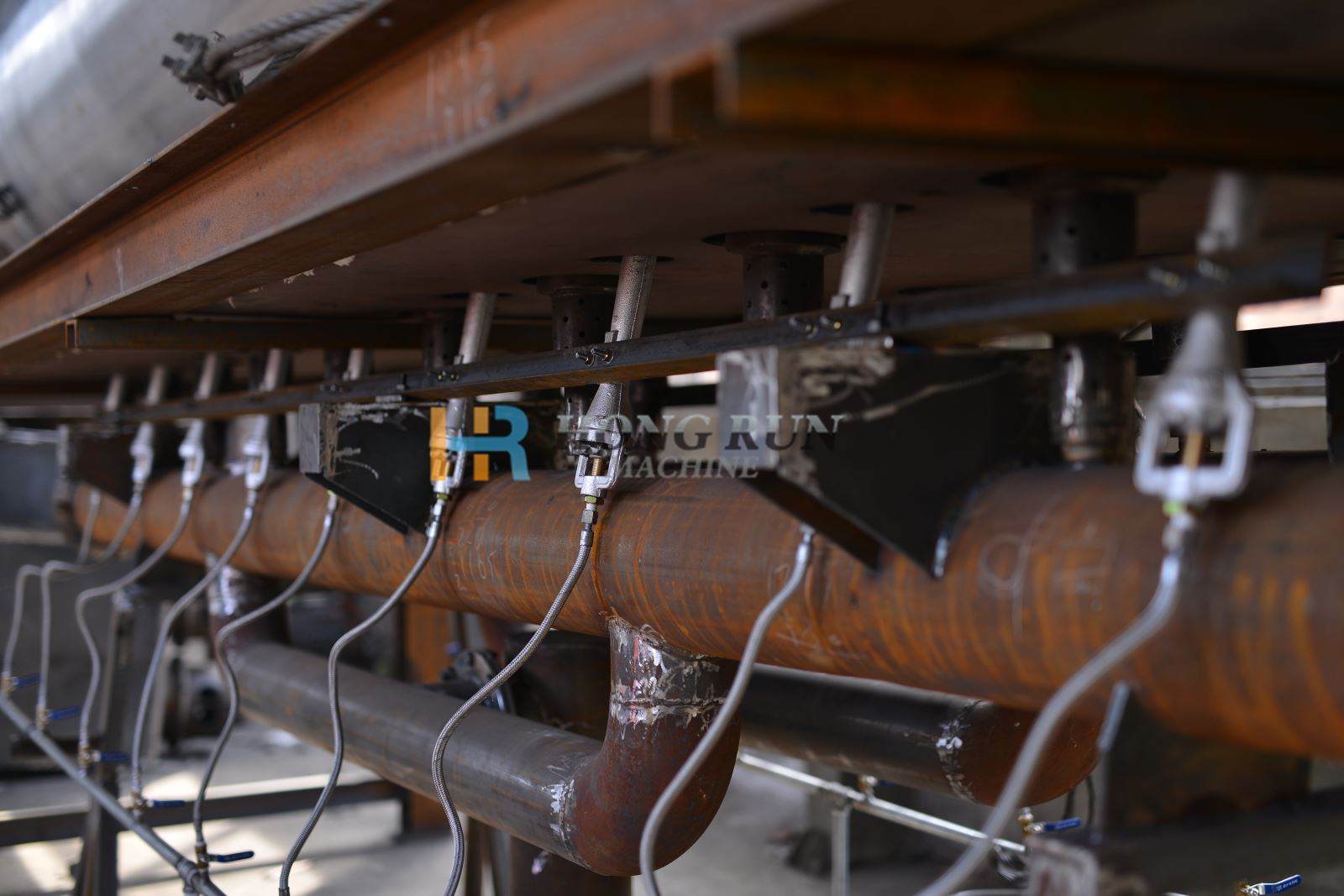

Environmental protection continuous carbonization furnace adopt gasification carbonization principle, adopt advanced smoke-free environmentally friendly carbonization process: the entire equipment from the gasification system (gasifier, spray tower, dust collector), purification system Leach, oil and water separator, filter), carbonization system (carbonized host, screw feeder, screw feeder, cooling machine, conveyor, finished cooling warehouse), control system (control cabinet), the entire carbonization process is automated production, automated operation.

Hongrun energy-saving environmental protection continuous carbonization machine has two significant advantages: First, the host capacity, high carbonation rate, strong production capacity, per hour carbonized rice husk about 1 ton; Second, low cost, cost Low practicality, to meet the initial entrepreneurial investment benefits of small objective requirements.

Continuous carbonization furnace belongs to an external heating drying and carbonization integrated machine. The flue gas generated in the entire production process is self-utilized, and the exhaust gas passes through the flue gas treatment device in the photo below. The whole process does not pollute the environment after technical improvement.

South African Customer Production Site, Click the Video below to See the Video of the Production Site.

Delivery Site of Continuous carbonization furnace exported to UK:

We also have different kinds of carbonization furnace, such as Hoist Carbonization Furnace, Horizontal Carbonization Furnace, Biochar Stove Machine, etc to meet the different requirements of customers. Click the Photo to see more information.

Hoist Carbonization Furnace

Horizontal Carbonization Furnace

Charcoal Making Production Line

Continuous Carbonization Furnace & Charcoal Ball Machine Production Feedback from South African

Welcome your inquiry! When you send us E-mail, please tell us the machine name you are interested and the raw material you have, so that we can recommend you with suitable machine and good price, thank you.

Email:

Email: